standard value of rockwell hardness test b of aluminum|rockwell a hardness conversion chart : makers Aluminum Alloy Hardness Chart. The table below provides typical Vickers hardness values measured with a Tianxing W-20 Vickers hardness tester for nearly 400 different grades of aluminum alloy materials . Quatro meses depois, Benchimol e Ana Clara começaram a namorar. Eles se casaram em 2005 e têm três filhas, uma de 9, outra de 7 anos e uma recém-nascida de 3 meses. A .

{plog:ftitle_list}

WEBO Altice Forum Braga, referência no norte do país, tem condições únicas e de excelência para a realização de congressos, espetáculos, concertos, feiras e todo o tipo eventos. . escritor e pagodeiro Afonso Padilha vai, novamente, rodar Portugal com o seu solo ‘E agora?. Em uma hora, Padilha fala sobre conflitos entre gerações .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . Aluminum Alloy Hardness Chart. The table below provides typical Vickers hardness values measured with a Tianxing W-20 Vickers hardness tester for nearly 400 different grades of aluminum alloy materials . Rockwell Hardness Standard Test. The Rockwell hardness test, . a 1/16 inch ball diamond indenter under a total test force of 100 kgf, is applicable to copper alloys, soft steels, aluminum alloys, and malleable iron. . The Mohs hardness is a standard for representing mineral hardness, first proposed in 1822 by German mineralogist Frederich Mohs. It is a standard used in mineralogy or gemology. . The Rockwell hardness test is .

ASTM Hardness Standards Reference Guide; Selecting a Hardness Tester. . Hardness Conversion for Rockwell B Scale or Low Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

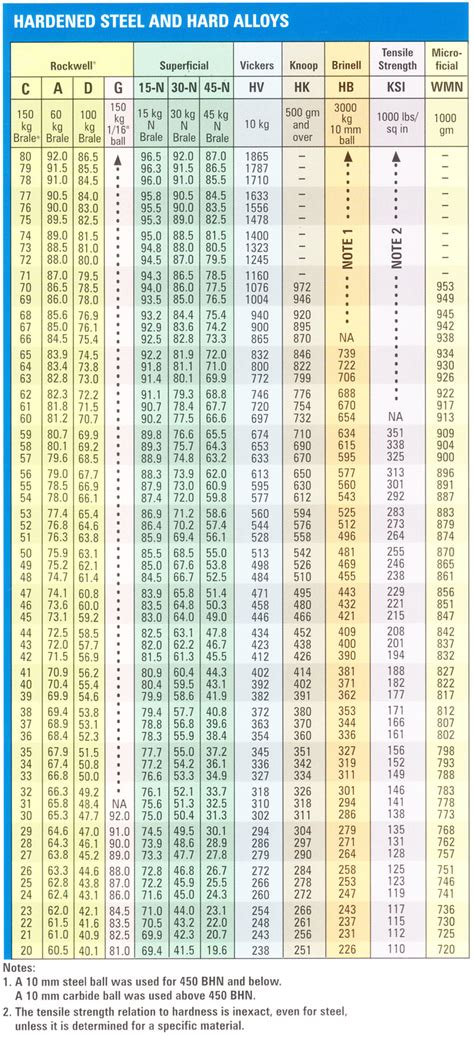

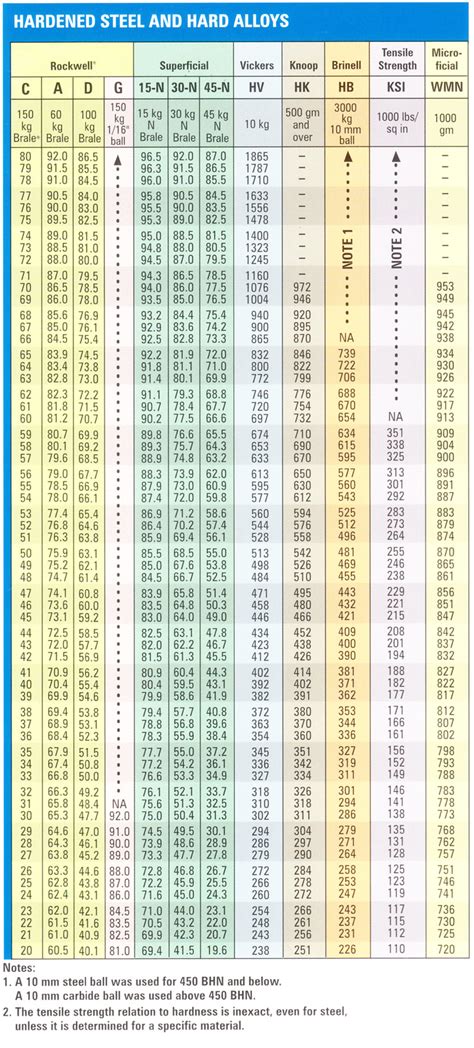

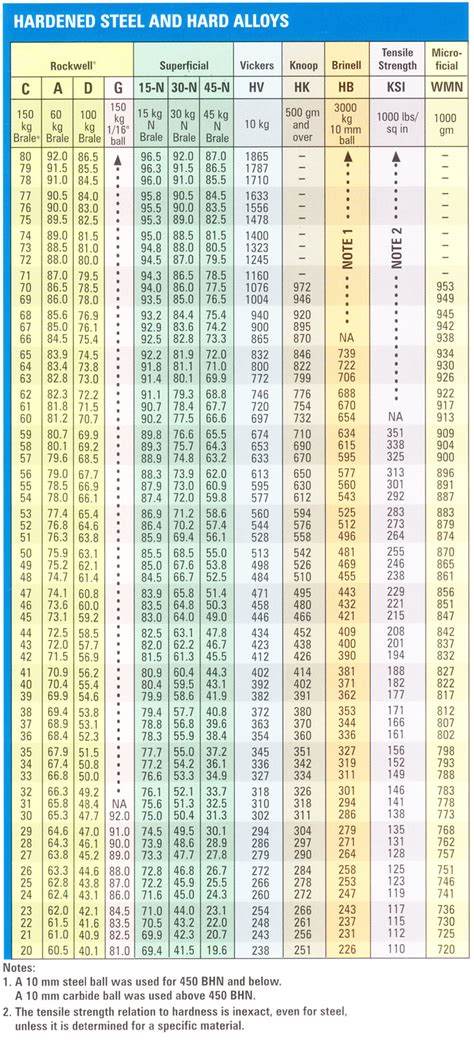

1.2 Conversion Table 2 presents data in the Rockwell B hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial . 1.12 Conversion of hardness values should be used only . both the Rockwell and Brinell hardness standards (Test Method E 18 and E 10, respectively) allow or require . 3. Rockwell hardness uses the depth of indentation plastic deformation to determine the hardness value index. A unit of hardness is 0.002 millimeters. When HB>450 or the specimen is too small, the Brinell hardness test cannot be used and the Rockwell hardness measurement is adopted instead. performing a Rockwell hardness test and/or a Rockwell super-®cial hardness test and displaying the resulting Rockwell hardness number. 3.1.7.1 Rockwell hardness testing machineÐa Rockwell hardness machine used for general testing purposes. 3.1.7.2 Rockwell hardness standardizing machineÐa Rock-

1.2 This test method includes requirements for the use of portable Rockwell hardness testing machines that measure Rockwell hardness by the Rockwell hardness test principle and can meet all the requirements of this test method, including the direct and indirect verifications of the testing machine. Portable Rockwell hardness testing machines that .

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Aluminium is approximately 240 MPa.40 40 Converted from Brinell Hardness Value Hardness, Rockwell B 60 60 Converted from Brinell Hardness Value Hardness, Vickers 107 107 Converted from Brinell Hardness Value Tensile Strength, . Aluminum, Al 95.8 - 98.6 % 95.8 - 98.6 % As remainder Chromium, Cr 0.040 - 0.35 % 0.040 - 0.35 %International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.The measurement showing the depth between the initial and the final indentation helps calculate the Rockwell hardness value of the aluminum hardness material. You can combine these indenters with a range of loads from between 15kgf to 150kgf, giving a total of 30 different Rockwell hardness scales. Vickers Hardness Test

Table 1: Typical values of different aluminum alloys per AMS 2658D [4]. Hardness of a part is measured using a typical Rockwell “B” hardness tester. The surface conductivity of aluminum alloys is typically measured using an eddy-current conductivity meter. Eddy current is a non-destructive testing technique

rockwell hardness scale for aluminum

rockwell hardness chart pdf

Rockwell B (HRB) Softer metals, Aluminum alloys, Non-hardened steels: Suitable for softer materials, fast . If a number falls between two hardness values, simply interpolate results to obtain an estimate. . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Rockwell A Hardness, Rockwell B 87 87 Converted from Brinell Hardness Value Hardness, Vickers 175 175 Converted from Brinell Hardness Value Ultimate Tensile Strength 572 MPa 83.0 ksi AA; Typical Tensile Yield Strength 503 MPa 73.0 ksi AA; Typical Elongation at Break 11.0 % 11.0 % AA; Typical; 1/16 in. (1.6 mm) ThicknessBefore a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up in accordance with the manufacturer's instructions: Especially it should be checked that: a) the plunger holding the indenter is capable of sliding in its guide; Indian Standard METALLIC MATERIALS — ROCKWELL HARDNESS TESTAluminium 6061 Mechanical Properties – Extruded Bars, Rods, Wire, Profiles, and Tubes: Standard: Aluminum Alloy and Temper: Specified Diameter or Thickness, in. Area, in2: Tensile Strength, ksi, ≥ (unless otherwise specified) Yield Strength (0.2 % offset), ksi, ≥ (unless otherwise specified) Elongation in 2 in. or 4xDiameter, ≥, % ASTM .The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; . Copper alloys, soft steel, aluminum alloys, malleable iron, etc. . getting the accurate hardness value for material using the Rockwell hardness value is highly dependent on understanding the working .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic Scales

rockwell a hardness conversion chart

hardness conversion chart pdf

Edificio chopin copacabana rio janeiro. Apartamento em Copacabana, Rio de Janeiro/RJ de 344m² 4 quartos à venda por R$ 9.699.000,00. 22021-001, Copacabana, Zona Sul .

standard value of rockwell hardness test b of aluminum|rockwell a hardness conversion chart